As a professional digital printed tea towel supplier, BLANC Tea Towel provides customers with the entire process of producing customized tea towels and dividing them into 8 steps.

Step 1, Weaving & Processing

Our tea towel production process starts with weaving to guarantee the quality of 100% pure cotton tea towels from the source. BLANC’s factory reserves a large amount of cotton yarn raw materials, which are then woven into cotton fabrics of different weights according to the needs of other customers, mainly including 195gsm and 265gsm. With nearly 20,000 square meters of cotton cloth reserves, it guarantees a complete supply chain and a short delivery cycle. Then, before digital printing on tea towels, the fabrics are processed according to customer needs, including washing and sizing.

Step 2, Design Draft Optimization & Adjustment

The patterns customers want to print on the tea towel are usually divided into photos, design drafts, logos, and other styles. Even some customers only have sketches or fundamental ideas, and the size of each pattern is different. Most of the commonly used tea towel sizes are 40x60cm and 50x70cm. Our designers will fully communicate with customers and optimize and adjust customer patterns such as cutting, color mixing, and design to achieve the best display on tea towels of different sizes.

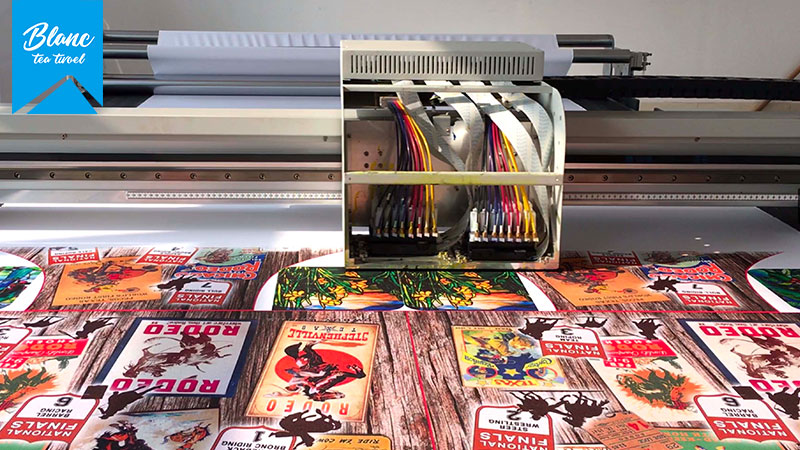

Step 3, Reactive Digital Printing

Every piece of BLANC tea towel adopts a reactive digital printing process. Compared with the traditional printing process, reactive digital printing has more advantages. It has the characteristics of brighter color, more environmentally friendly dyes, higher colorfastness, faster proofing, softer touch, better quality, and smaller orders. You can also learn more: The Advantages Of Reactive Digital Printing.

Our factory has 6 reactive digital printing production lines, which can meet different types of printing needs and guarantee a faster delivery cycle.

Step 4, Fine Processing

After the active digital printing is completed, the tea towel will enter the steaming and washing process. The unique steam wetting system of the BLANC factory is suitable for the aging and fixation of reactive dyes. The characteristics of steam washing are that the printed fabric has a softer feel, brighter colors, and higher colorfastness.

Then go into the stentering and heat setting process to print fabric smooth and full size.

Step 5, Cutting & Sewing

Now we will enter the cutting and sewing of printed fabrics. First, the worker cuts the tea towels according to the size and then irons each tea towel to make the product smoother.

Then start sewing. The whole sewing process includes Hemming sewing, Customized labels, Sew-in loops, Cutting thread, etc., until a complete tea towel is made.

Step 6, QC & QA

The quality inspection process is an indispensable step before each tea towel is delivered to the customer. First, the quality inspector will inspect all tea towels one by one, including the clarity of the printed pattern, whether the sewing is straight, whether the logo label is complete, etc. Then, of course, after the packaging is completed, each tea towel must be tested by a needle detector to ensure the quality of the product and the safety of the user.

Step 7, Product Packaging

After each tea towel has passed the quality inspection, we package the product according to the customer’s requirements. Packaging types include PE bag, OPP bag, PVC bag + insert card, Gift box, etc., and can also be customized according to customer needs. After the tea towel passes the needle detector, put the cartoon into it.

Step 8, Fast Delivery

After all the above procedures are completed, it will enter the final delivery link. Our sample production cycle is about 10 days, and all products will be delivered within 30 days after the sample is confirmed.

To allow customers to receive their beloved tea towels faster, we usually use the fastest air freight to ship to customers, including DHL, UPS, FedEx, TNT, etc.